Thu, Jul 17, 2025

[Archive]

Volume 17, Issue 2 (June 2020)

IJMSE 2020, 17(2): 16-26 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Katal R, Azizi A, Gharabaghi M. Investigating the Leaching Behavior of Copper from Chalcopyrite Concentrate in H2SO4/CuCl2 Media. IJMSE 2020; 17 (2) :16-26

URL: http://ijmse.iust.ac.ir/article-1-1568-en.html

URL: http://ijmse.iust.ac.ir/article-1-1568-en.html

Abstract: (18942 Views)

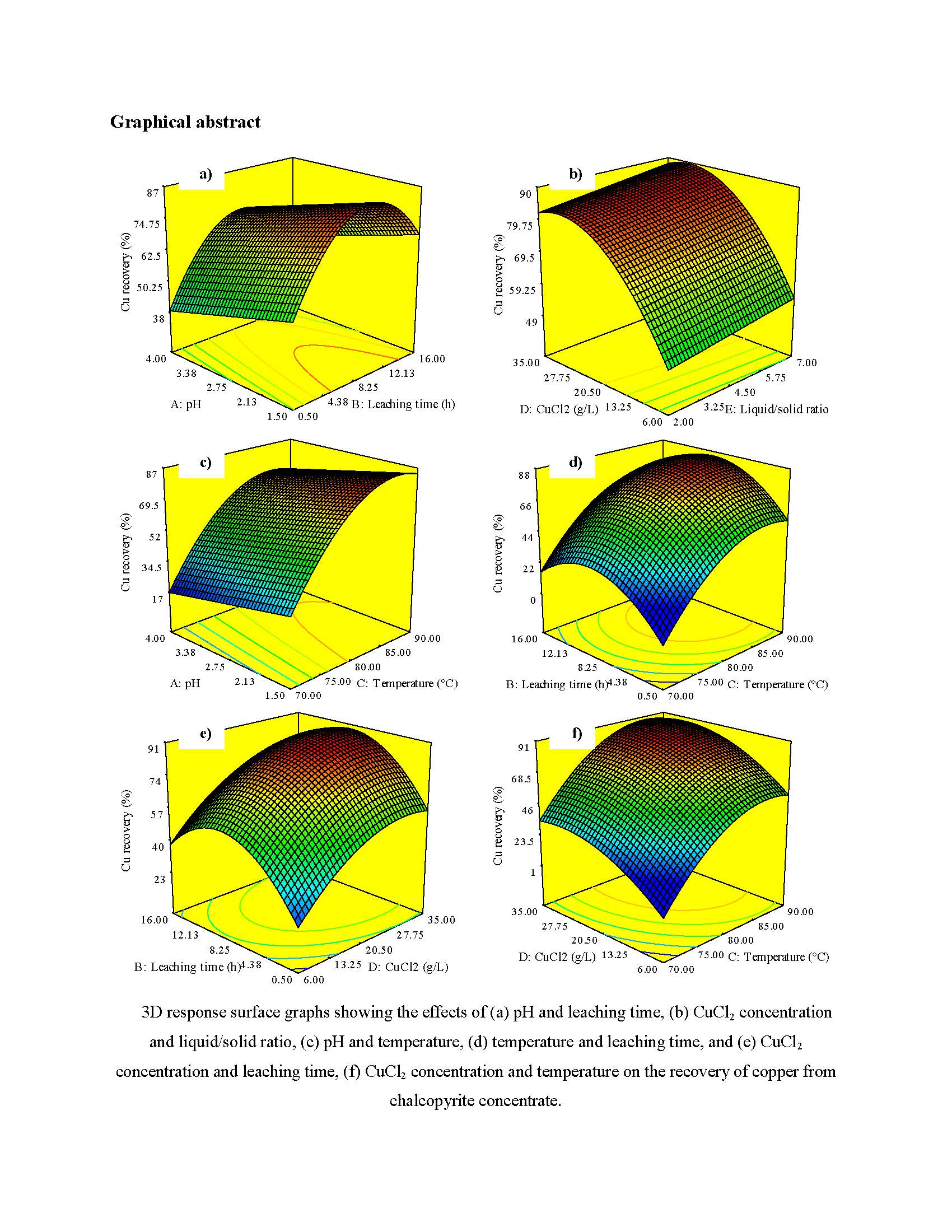

Present paper investigates the dissolution behavior of copper from chalcopyrite concentrate sample using cupric chloride solution in detail. Response surface modeling (RSM) in combination with d-optimal design (DOD) was utilized for modeling and optimizing the cupric chloride leaching process. At first, a quadratic polynomial model was developed for the relationship between the recovery of copper and influential factors. The predictions indicated an excellent agreement with the experimental data (with R2 of 0.9399). Then, the effects of main factors including pH (1-4), liquid/solid ratio (2-7 mL/g), temperature (70-90 °C), CuCl2 concentration (6-35 g/L), and leaching time (0.5-16) were determined. The findings demonstrated that the temperature and CuCl2 concentration were the most effective factors on the dissolution rate of copper from chalcopyrite sample, while liquid/solid ratio had the lowest impact. The recovery of copper increased linearly with an increment in the liquid/solid ratio and the decrease in the pulp pH. Additionally, the recovery enhanced by increasing the temperature and CuCl2 concentration owing the generation of Cu–Cl complexes species and reached a plateau point and then almost remained unchanged. Meanwhile, it was found out that the recovery of copper was independent of the interaction between factors. Moreover, the optimization of leaching process was carried out by Design Expert (version 7) software and desirability function method and the highest recovery of copper was found to be about 86.1% at a pH of ~1.4, temperature of 89 °C, liquid/solid ratio of 6.8 mL/g, CuCl2 concentration of 21.79 g/L and leaching time of ~8 h.

Keywords: Copper leaching, Chalcopyrite concentrate, HydroCopper® process, Cupric chloride, D-optimal design (DOD)

Type of Study: Research Paper |

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |